With smart grid, we are able to predict energy needs with accuracy

Supervisory Control and Data Acquisition or SCADA has completely transformed how industrial processes and vital infrastructure systems are monitored and managed. In many industries, including manufacturing, energy, transportation, and water treatment, SCADA systems are essential and real-time visibility into the operation of the smart grid is provided through it. Data from various grid nodes, such as electricity production, distribution, and consumption, are continuously monitored by them.

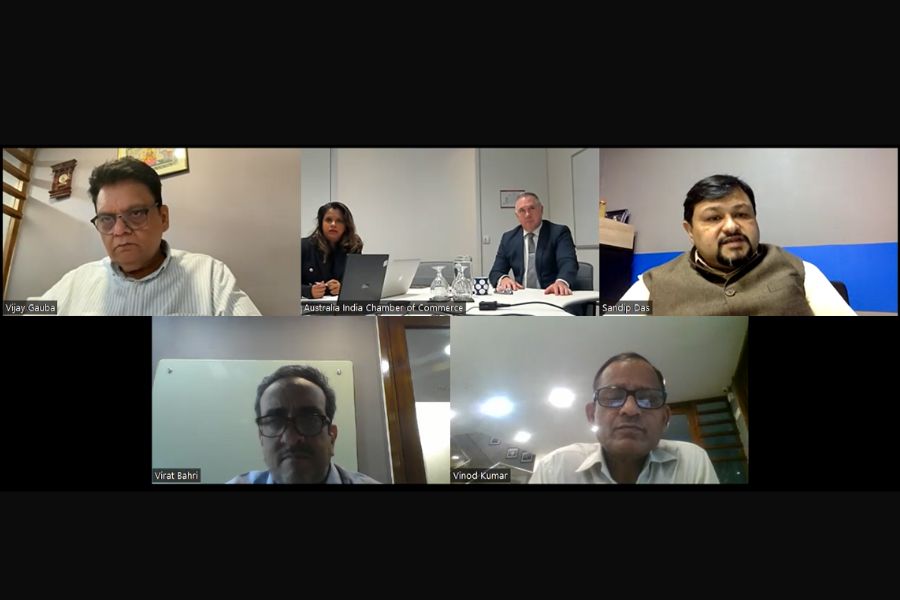

India Business and Trade spoke with Mr. Kumar M, CEO – Smart Grid Analytics Pvt. Ltd. & Armax Automation Pvt. Ltd., on how a technology such as SCADA systems makes it possible to remotely operate grid components, which enables automation of energy output.

The entrepreneur also stated that the implementation of Smart Grid is the need of the hour. Smart Grid can forecast tomorrow’s prediction on energy requirements with accuracy, enabling the operator to assess how much energy is generated and what is the dependability of the plants which are connected to the grid.

Photo Source: Kumar M.

IBT: How does SCADA system impact the regulation and safety aspects of the electricity grid or the grid system in itself?

Kumar M: SCADA is a pretty old technology. It stands for Supervisory Control and Data Acquisition wherein these software were actually built for a process industry like steel, cement, sponge and and other industries. But with the advent of renewables, that is solar, wind and battery energy storage systems, what is happening is the controlling portion is actually very less compared to the data acquisition. There is humongous data which has to be acquired from the field and then an intelligent decision has to be made out of it. There are other products within grid-controlling systems, like PPC EMS. The maturity of SCADA has not been as wide as it should have been and the reason is conventional systems were made for process industries and the SCADA systems which are being used right now for renewable energies are not capable of extensive data logging, which is meant for 25 years. If you take any asset, its value grows into a tangible one.

What we have done with our own product called One SCADA, wherein it is built on entirely mean language. So what it does is it uses a big database, unlike conventional SCADA. So when you have a big database, you can actually do a flexible search, you can actually store a lot of information, pick it up, and then the way it helps is you can seamlessly integrate to the grid transfer data on multiple protocols. It could be IEC 10, IEC 4, IEC 61850 and then also for the grid regulatory like the CEA has come out with a grid code compliance, wherein PPC would be a part of it, that is Power Plant Controller. Unlike thermal and other industries, they have AVR and AGC, i.e., Automatic Voltage Regulator and Automatic Generator Controller, which are standard, approved and have been in the system for a long time.

The use of PPC is becoming more prevalent due to the increasing presence of renewable energy sources entering the grid. As a result, the short circuit ratio of the grid decreases, leading to an increase in instability. This instability could potentially cause grid failure if power plants underperform or fail to react to grid parameters. To address this issue, PPC is a product that can be used to comply with CA statutory requirements for active power, reactive power, power factor, and voltage control. It can also be integrated into modern SCADA systems, which allow for easy input of set points for different grid codes. While the controlling factors and bands may differ between countries, the grid codes themselves remain largely the same. Additionally, 1 second-resolution data logging can be utilized to ensure grid safety in the event of any issues, enabling easy identification of the root cause. All of these benefits are made possible through the use of SCADA technology.

IBT: Has the adaption to the smart grid matured? And where does India stand in terms of implementation of the smart grid?

Kumar M: I would like to mention a couple of interesting points regarding the Power Plant Controller (PPC). Other countries had already implemented PPC in their grid codes back in 2014 and 2015, while India implemented it in 2020. By gaining knowledge from other countries’ grid codes, we have successfully implemented it here in India.

In India, there are multiple departments responsible for different aspects of the grid, such as safety, trading, and policies. However, there has been a recent transition where Power System Operation Corporation Limited (POSOCO) has been renamed as Grid Controller of India. All the rural load dispatch centers have also come under the grid controller, ensuring that all team members work towards the single agenda of ensuring grid code safety. This is a great move by the Indian authorities.

Compared to global implementation, yes, smart grid concepts have been implemented in Europe, Latin America and parts of East Asia a long time back. But we are catching up very soon. We are there right now with a good resilient network. And in terms of maturity, I could say that our government and industry framing the agreements are actually pretty good at catching up. We are at a very progressive scale compared with respect to test procedures, implementation, and checking of the systems online.

Using the smart grid has various benefits. One of them is the ability to accurately predict the energy demand for the following day. This information helps the operator understand how much energy is required, how much they can generate, and the reliability of the plants connected to the grid.

Let’s say you want to rate a plant’s dependability. If you give it five stars, it means it’s very dependable. Four stars are for semi-dependable plants, while three stars are for undependable ones. To accurately predict tomorrow’s energy supply and consumption, we need to consider various factors, such as the day of the week, time of the year, seasonal influences, and holidays. Understanding these patterns is crucial in forecasting energy demand and supply. One of the models used for this is Armax, which stands for Autoregressive Moving Average Exogenous Model.

IBT: To put things in perspective, let’s compare the disruption of electricity caused by the traditional system of delivery to that caused by the smart grid. If you could just give us a general concept.

Kumar M: The percentage of error, I would say conventionally, we are not doing it under a single umbrella. The error percentage could be between 7 to 10 % and if you actually do it in one single umbrella, the error percentage could come down to 2 to 3 %. And when we say a substantial amount of 5 to 6 % could be lakhs of units saved which can actually be sold in the market or can be stored in the battery. Energy storage systems can be used for reactive power compensation when there is an abnormality in the grid.

IBT: how do you integrate artificial intelligence, and data analytics into the smart grid systems to establish smart grids?

Kumar M: Yeah, so for precisely answering that question, whatever we are doing over this is on the entire SAAS base, that is Software As A Service model where it resides on the cloud. Once the data is aggregated from the field, these A and ML technologies will be able to tell you how the device is performing on a historical basis and how it’s going to perform. So your preventive prescriptive maintenance also will come, predictive maintenance also will come, that when the device is going to fail and what do you need to actually to have in stock to ensure that even if it fails, you have a lesser downtime, so that increases your productivity and revenue.

IBT: You have a company called Smart Grid Analytics Limited. How do you address different challenges with this new platform and what kind of different solutions are you providing under this company?

Kumar M: We have multiple modular solutions which actually work into a bucketing kind of system, where you have data aggregation from the field. That’s one solution which will pick up the data. The other addition is online SCADA. Instead of having SCADA on-premises, you can have it online, which actually reduces the cost of a burden on your IT assets. And then we have CMS (Central Monitoring Solution) where you have multiple plants. The multiple plant data is aggregated and then it is shown in a single window with predictive and prescriptive analytics. And then that module talks to another module, CMMS on the back end through APIs, where any downtime of an inverter that is a revenue-generating equipment goes down, automatically a work order is created. And then the CMS will also have Digital Twin which will actually give you a precise forecast. Since we do a digital twin of the entire plan, they get a better forecast in terms of committing to the grid authority saying I will be able to generate this much amount of power tomorrow. And based on that, we are also working on Digital Twin for electrolyzer and hydrogen, wherein we can tell how much capacity of hydrogen will you be able to produce tomorrow based on the weather forecast of tomorrow.

We have a comprehensive understanding of the number of cylinders that can be manufactured and sold, as well as their corresponding prices. Additionally, our Intelligent Bidding module allows for connectivity with online trading or round-the-clock power. During specific times when power needs to be dispatched, you can earn a higher revenue per unit compared to regular generation hours. These are the technologies that we are currently developing, and they make up our unique selling proposition.

Kumar M. completed his M.S. in automation control from Karlstad University, Sweden in 2003. He did his

Leave a comment