Boost to manufacturing sector is the need of the hour

India’s focus on manufacturing and domestic value addition is gaining momentum, with the recognition of being the Sixth Manufacturing Superpower. Despite a decline in the percentage of manufacturing in GDP, there has been a revival, including a sudden growth in 2021. The sector has shown impressive growth and has attracted increased FDI inflows, supported by domestic reforms.

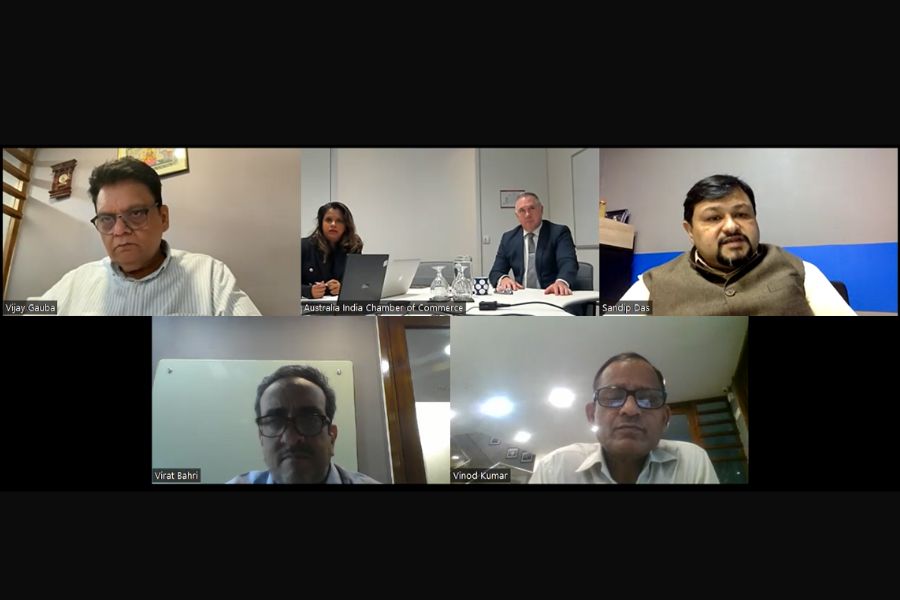

Image Source: Shutterstock

Is India ready to relinquish the old narrative of ‘missing the manufacturing bus’? Is India preparing for take-off to higher growth in its manufacturing sector with more value addition? These questions have become more appealing in light of a speech, on May 10, 2023, by the Hon’ble External Affairs Minister Shri S Jaishankar. He mentioned that the focus has to be on manufacturing and increasing domestic value addition, as no country can enhance or sustain its position by compromising its manufacturing capabilities.

Experiences of several developed countries, including the US, those in Europe and particularly of East Asian Tigers, have long exemplified that sustained economic growth cannot be achieved by merely feeding on the positive outcomes of the services sector alone. Services act as input in manufactured items, but a Strong Will to develop a more extensive manufacturing base is needed to be a Superpower. ‘Make in India’ began with the same objective. But, more apparent revival and growth prospects are visible in India’s domestic manufacturing, especially, since 2020.

India is now seen as the (since 2014) Sixth Manufacturing Superpower – gradually growing – its manufacturing output share doubled in 20 years (2002-21). This share has also been stable in the 2.5-3 per cent range since 2009. Even though the percentage of the manufacturing sector in GDP declined in the past decade, it started to pick up marginally in 2019. The declining year-on-year growth rate of the sector witnessed sudden growth of 21.6 per cent in 2021 over 2020. This could be an outcome of the vent out of pent-up demand during the pandemic.

But, perhaps, this has not been just a temporary revival phase. This is because the real gross value added of manufacturing has shown impressive growth of 11 per cent in FY 2023 compared to FY 2020, and the estimates for the second half of 2023 refer to a growth of 3 per cent. FDI inflows in Indian manufacturing also increased from $12.1 billion in FY2021 to $21.3 billion in FY2022 as part of the expansion policies of developed economies. Although FDI declined in the first half of FY2023 (owing to the Russia-Ukraine conflict and slowdown in demand), it remained above pre-pandemic levels owing to domestic reforms.

| India is Among the Top 10 Manufacturing Superpower | |

| Country | 2021 (Percentage change over 2002) |

| China | 30.3 (+21.7*) |

| US | 15.6 (-9.6) |

| Japan | 6.2 (-8.6) |

| Germany | 5.0 (-2.0) |

| S.Korea | 2.9 (+0.2) |

| India | 2.8 (+1.4) |

| Italy | 2.0 (-1.7) |

| UK | 1.7 (-2.0) |

| France | 1.63 (-1.9) |

| Russia | 1.60 (+0.7) |

Source: World Bank, UNCTAD (Global Share of Manufacturing Output/Value Added); *change over 2004

Source: World Bank

The Government’s ongoing measures to facilitate business growth in India, increase value addition and promote exports of Indian manufactured goods, say via the Production Linked Incentive (PLI) scheme, could be given credit. New schemes like Remission of Duties or Taxes on Export Products (RoDTEP) have been launched to provide more relief to the exporters who manufacture within India.

Interestingly, Foreign Trade Policy 2023 has included certain manufacturing sector-specific boosting measures such as for apparel, EVs, etc. MSMEs, local businesses and small vendors are particularly given good priority, which is a welcome step and supports the Government’s ongoing efforts to create resilient domestic supply chains in manufacturing. So, there is perhaps a ray of hope among businesses that it is feasible to manufacture or make within the country if done strategically. Illustratively, India is now the second-largest manufacturer of mobile phones – the sector for which the first PLI scheme was launched.

To regain success in manufacturing, there needs to be a reorientation in mindset concerning the right conceptualizing and facilitation of ‘Make in India’ and ‘Manufacture in India’. Does it primarily mean import substitution or protection or decoupling from China? Because making in India is a more extensive work and a bigger responsibility for the nation as a whole. We need to be cognizant of the kind of products finally manufactured in India as they should be capable of clearly branding Indian culture, designing, IT and entrepreneurial skills, market capability, innovation, quality, scale, standards, labour usage, etc.

In other words, we need to develop ourselves and have homegrown confidence to have massive production so that domestic and export demands align more strategically, involving partners and stakeholders from businesses, Government, academics, etc.

This requires a more profound identification of sub-sectors in manufacturing as per our higher comparative advantages and export potential (as per partner countries) and their mapping with those sub-sectors within India, which can provide the required intermediate inputs to develop India’s own value chains. However, India can continue to source mostly those inputs globally available at lower costs.

We also need definite answers to these questions to rise as a manufacturing superpower: Are current improvements in infrastructure and support to start-ups enough to offer sustainable solutions? Are our businesses equipped to match international best practices regarding costs, Industry 4.0 standards, AI & innovations, and product quality? What about our stance on imports from China and the Rest of the World? Better data reporting and practical long-term resolutions are needed to build strong domestic manufacturing value chains.

The need of the hour is to boost the manufacturing sector’s competitiveness on a larger scale and fully utilize and brand the reputation of making in India for the world, especially if we are determined to achieve the ambitious target of India’s exports of $2 trillion by 2030.

Here are some of the specific Policy Options to boost manufacturing in India:

- As most government incentives for the manufacturing sector are now via the PLI scheme mostly for the new age segments, including electronic items such as mobile phones, hearables, wearables, IT hardware, high-efficiency solar PV modules, advanced chemistry cell batteries, speciality steel, electric vehicles, etc., Indian industry and policymakers should focus on building more new modern-facility based factories (as well as revamping existing viable ones) in these technology and innovation-driven sub-sectors.

- A larger scale of production should be the way forward. India has been mainly considered as the assembly centre or workshop. Still, in specific sub-sectors, such as mobile phones, it is ready to use its manufacturing capabilities to boost its exports further. For instance, manufacturing iPhones in India could help the country to move up the ladder to be both a manufacturing and export hub.

- However, the Indian manufacturing sector’s success should no longer depend solely on custom-duty changes.

- In the case of traditional sectors such as textiles and apparel (T&A), India has a presence in entire value chains. Thus, T&A can be one of the torchbearers to lead India’s self-sufficiency in production under the ‘Make in India’ agenda.

- Allowing a significant number of foreign players to invest in India may prove highly beneficial in creating a suitable ecosystem of supporting businesses, similar to the case of Samsung’s investment in Vietnam. Over time, by launching Technology Upgradation Programmes and Sourcing Fairs in collaboration with the Vietnamese Government, Samsung was able to secure linkages with Vietnamese firms and suppliers for obtaining intermediate goods. Further, government training and development programmes helped build a domestic ecosystem of ancillary suppliers in Vietnam. Similar activities could immensely boost manufacturing in India and help to create better linkages between local MSMEs and big local players as well as multinational companies.

- Better mechanisms are needed to encourage as well as reward those start-up manufacturing companies who bring innovative technologies on board and provide environmentally friendly sustainable products with higher value-added content domestically in terms of design, R&D, etc.

- More investment is required to regain power in the machine tool segment; More investment is needed to build world-class infrastructure and adequately implement the PM Gati Shakti Plan – the most important aspect for improving the business climate and strengthening the manufacturing base in India.

____________________________________________________________________________

Dr Neha Gupta is a Fellow of the International Council for Research on International Economic Relations (ICRIER). Views expressed are personal.

Leave a comment