Banana Waste Innovation: Sustainable Solutions for Manufacturing

The innovative utilization of plant waste, particularly banana waste, in various industries presents a transformative opportunity for sustainable manufacturing. This shift not only addresses environmental concerns but also opens up new avenues for economic growth and job creation. By repurposing agricultural residues, including banana waste, into textiles, bioenergy, and construction materials, we pave the way for a greener, more prosperous future.

Image Source: Pixabay

In recent years, there has been a shift towards using plant waste for sustainable manufacturing, driven by environmental concerns. Agricultural residue management is a key challenge, with waste being utilized in sectors like textiles to reduce environmental impact. Natural fibers, especially those from waste materials, offer a sustainable option for clothing production due to their comfort, mechanical characteristics, and biodegradability. Banana waste, like pseudo-stems, poses environmental challenges, but can be converted into fibers for textiles, bioplastics, and other products, promoting a circular economy and creating employment opportunities. This approach not only reduces environmental pollution but also benefits farmers financially and contributes to the multi billion-dollar apparel industry’s growth.

India, with its vast agricultural landscape, generates a significant amount of plant waste annually. However, instead of being a burden on the environment, this waste is increasingly being seen as a valuable resource. Through innovative approaches and sustainable practices, various industries are now utilizing plant waste to develop a wide range of products. This shift towards utilizing plant waste not only helps in waste management but also contributes to the development of eco-friendly and sustainable products.

Banana Waste: A valuable resource for diverse industries

The focus on using plant waste for sustainable manufacturing is part of a broader trend in the scientific community towards environmental preservation. This shift is underscored by the depletion of finite fossil fuel sources and the need to mitigate environmental pollution. Agricultural residue management is particularly challenging due to the sheer volume of waste generated.

In the textile sector, the utilization of agricultural waste, such as banana stems, offers a sustainable alternative to traditional fibers like cotton. Banana fibers not only reduce environmental impact but also contribute to biodiversity conservation by reducing monoculture farming.

Another innovative use of agricultural waste is seen in the creation of pads that can decompose within six months. The pads, made from banana skin, offer a soft feel and help prevent environmental contamination from hazardous menstrual waste. This dual benefit of agricultural waste utilization underscores the importance of repurposing agricultural residues to achieve environmental sustainability and economic benefits in various sectors. Additionally, both approaches have the potential to create new job opportunities, particularly in regions where these agricultural practices are prevalent, contributing to local economic development.

Similarly cotton waste, like banana waste, presents a valuable opportunity for energy generation. Both agricultural residues can be converted into energy through various processes, such as briquetting, pyrolysis, and anaerobic digestion. This presents a sustainable solution to reduce reliance on finite fossil fuel sources and mitigate environmental pollution.

Moreover, the composition of cotton waste is similar to other lignocellulosic feedstocks, making it suitable for bioenergy production. Studies suggest that cotton waste has the potential to be used for bioethanol production, highlighting its versatility in energy generation. However, similar to banana waste, proper pre-treatment strategies are necessary to reduce the lignin content in cotton waste for efficient conversion.

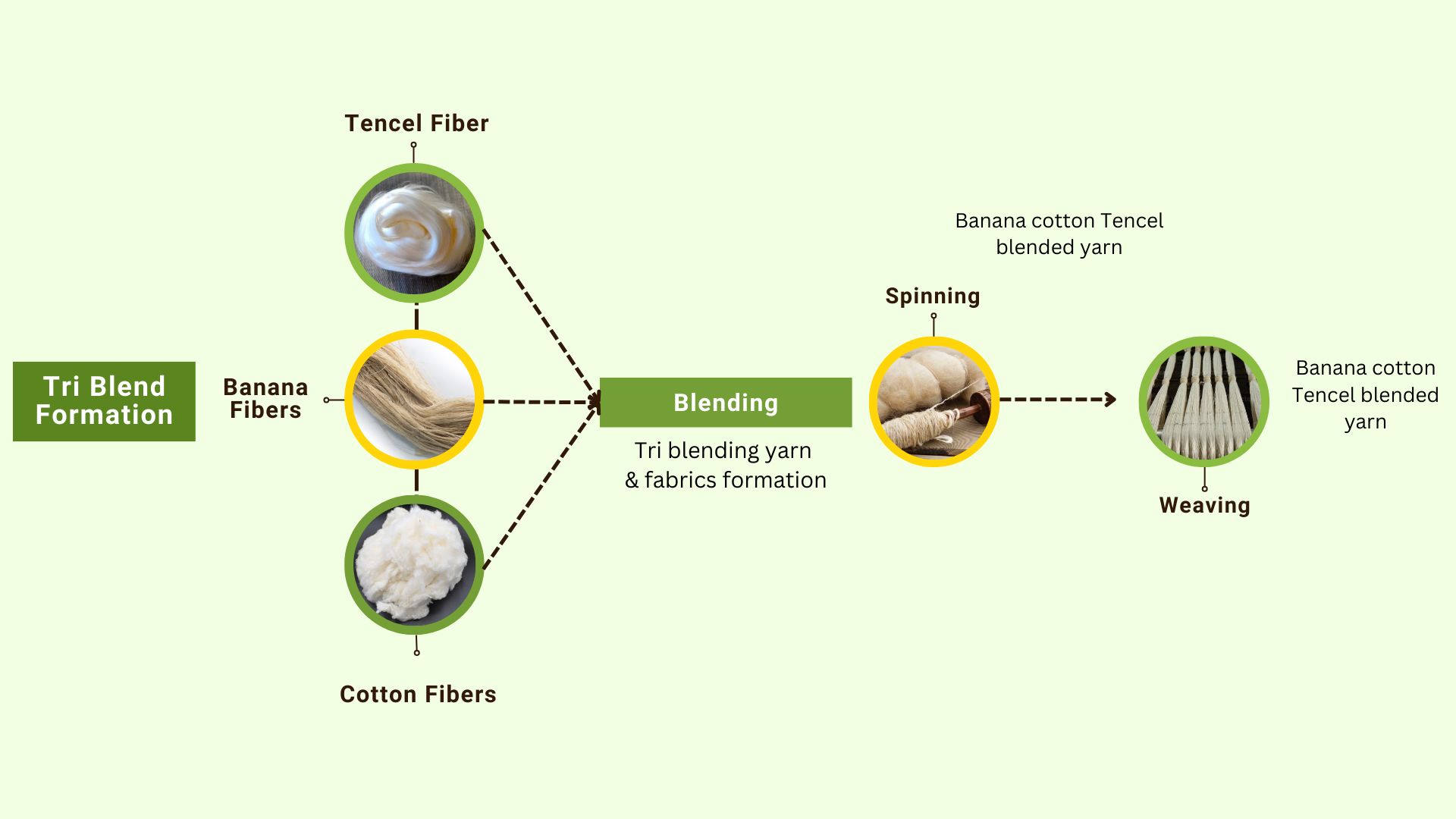

In various studies, an innovative approach has been explored to repurpose banana agro-waste by creating eco-friendly yarns and fabrics. Banana fiber is blended with cotton and regenerated cellulosic fiber (tencel) in varying ratios to produce high-quality yarns.

To enhance the banana fiber’s properties, it undergoes a process of boiling in distilled water to soften it, resulting in improved feel, strength, and reduced weight loss. Three blend ratios (10%, 20%, and 30% banana fiber by weight) are tested to produce Banana: Cotton: Tencel blended yarns.

These blended yarns exhibit superior mechanical properties compared to benchmark Cotton: Tencel 50:50 yarns. The 20% banana fiber blended yarn shows particularly promising results, with approximately 11% higher yarn bundle strength, 8.62% higher single yarn strength, and 22.90% better yarn quality index analysis compared to the benchmark.

Fabrics made from these blended yarns demonstrate notable improvements, including 6.61% higher tear strength, 18.8% more air permeability, 20% more elongation, and 12% higher tensile strength compared to Cotton: Tencel blended fabrics. This approach underscores the potential of using banana fiber in textile manufacturing to achieve both environmental and economic benefits without compromising on performance.

Similarly, in construction, concrete and masonry waste, along with agricultural waste, are recycled to produce sustainable concrete. This concrete is reinforced with plant-based fibers and supplemented with wood chips, further enhancing its environmental credentials. Additionally, the use of ash from burnt rice husks as a cement substitute reduces carbon dioxide emissions, contributing to a greener construction industry.

Adding to the array of sustainable solutions, scientists have successfully utilized tea and banana waste to produce non-toxic activated carbon. This eco-friendly material finds applications in industrial pollution control, water purification, food and beverage processing, and odor removal. Unlike traditional methods, this process avoids the use of toxic agents, making the activated carbon cost-effective and safe for various uses.

This highlights the potential of utilizing plant waste to create valuable products, underscoring the importance of repurposing agricultural residues to achieve environmental sustainability and economic benefits in various sectors.

Green Revolution from Plant Waste

Harnessing plant waste for sustainable manufacturing presents a dual opportunity to address environmental concerns and tap into a lucrative, booming market. With a shift towards eco-friendly practices, industries are increasingly turning to plant waste, such as agricultural residues and banana stems, as valuable resources for creating innovative products.

These materials offer sustainable alternatives to traditional fibers and construction materials, reducing environmental impact and promoting biodiversity conservation. Moreover, the conversion of plant waste into high-quality textiles, bioenergy, and construction materials not only helps in waste management but also opens up new markets and revenue streams. This trend towards utilizing plant waste reflects a broader movement towards sustainability and presents a promising avenue for economic growth and environmental stewardship.

Embracing the potential of plant waste for sustainable manufacturing represents a pivotal step towards a greener future. By harnessing agricultural residues and innovative processes, industries can not only mitigate environmental impact but also tap into a burgeoning market for eco-friendly products. This shift underscores the importance of reimagining waste as a valuable resource, paving the way for a more sustainable and prosperous tomorrow.

Leave a comment